Balti Spoon produces decorative wood surface veneers. Veneer is a very thin sheet of wood with a beautiful pattern. The standard thickness of the sheet is 0.55 mm. Surface veneer differs from the veneer used in the plywood industry by the considerably more valuable raw material and the significantly higher quality requirements.

We hand-pick each log for our production and give as much added value as possible to the logs. One high-quality log can provide a valuable surface layer for scores of furniture sets, compared to solid wood furniture, however, the same log could only be used to make one set.

Balti Spoon produces rotary veneers from birch and sliced veneers from oak, beech, birch, ash, pine, maple, alder, larch, aspen, and other species.

Our company also represents the US division of the Möhring Group which allows us to offer their selection, including natural veneers such as Am. Walnut, Am. Cherry, Am. White Oak, Am. Red Oak, Am. White Ash, and a wide selection of other veneers. We can offer selection of products from one place to all our customers.

In addition to raw veneers, we also sell custom-made spliced veneer sheets.

Only marked products are available as certified

Only marked products are available as certified

Rotary birch veneer is one of our main products. Nordic birch has an even, light colour and a smooth cutting surface. Birch is a durable but elastic wood, it can be pressed, bent, and polished.

Balti Spoon produces rotary birch veneer in many different quality grades depending on the customer’s wishes. Even though the standard thickness is 0.55 mm, we also produce rotary veneer in thicknesses up to 2 mm. We produce veneer sheets in widths of 8-207 cm and lengths of 40-320 cm.

Sliced veneer is of a very elegant texture and usually used to cover furniture or parquet. We mainly produce sliced veneer from oak, beech, birch, ash, pine, larch, maple, alder, and aspen. The standard thicknesses are 0.55, 0.7, 0.9, and 1 mm. We can also cut veneer in custom-made thicknesses. The widths of the veneer sheets range from 10 to 40 cm, the lengths from 50 to 400 cm.

Matching of wood patters in order to create decorative surfaces is a centuries-long skill of furniture-makers. Today, spliced veneer sheets are mainly used for this purpose. Balti Spoon offers spliced veneer sheets of different structures: bookmatch, slipmatch, randommatch, etc. The customer selects the desired species and the dimensions of the spliced veneer sheet. We use the edge gluing technology with different type of glue, depending on customer needs.

Balti Soon is not a regular timber company. We are a global decorative veneer producer and have at our disposal the technologies for highlighting the beauty and unique patterns of wood. We are processing a luxurious material which will be decorating people’s homes and working spaces and making them cosier.

step one

Very few logs are suitable for veneer production, just a few percentages of the felling volume. We purchase thick, straight, undamaged logs with very few knots. When planning the production operations, logs are examined one-by-one to decide the thickness of veneer made from the log.

step two

We use peeling or slicing technology for making veneer. Selection of Balti Spoon products includes veneers of different thicknesses from 0.55 mm to 2 mm. Rotary veneer is only made of birch, sliced veneer of different species out of hardwood and softwood, such as oak, birch, pine, beech, and larch

step three

Before placing to the warehouse, the veneer bundles are sorted and divided into quality grades. Some of our clients purchase veneer and process it further themselves. Quite a few customers, however, order ready-made spliced veneer sheets from Balti Spoon. Those veneer sheets are glued together based on the dimensions and structure requested by the customer and used to cover doors, wall panels, or worktops etc.

-

Birch brown heart

Read more -

White Beech quarters

Read more -

White Beech crown

Read more -

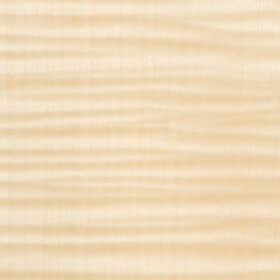

Sycamore quarters

Read more -

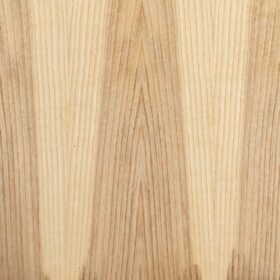

Pine quarters

Read more -

Pine crown

Read more -

Knotty Spruce

Read more -

Knotty Pine

Read more -

Figured Sycamore quarters

Read more -

Figured Sycamore crown

Read more -

Figured Birch quarters

Read more -

Figured Birch crown

Read more -

Figured Birch peeled

Read more -

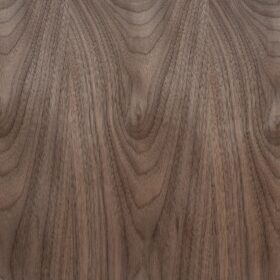

Walnut mismatch

Read more -

Walnut bookmatch

Read more -

Walnut (crown) slipmatch

Read more -

Smoked Oak Bookmatch

Read more -

Birch peeled slipmatch

Read more -

Red Oak Bookmatch

Read more -

Oak Rustic mismatch

Read more -

Oak mismatch

Read more -

Oak (quarters) slipmatch

Read more -

Maple mismatch

Read more -

Cherry bookmach

Read more -

Birch peeled mismatch

Read more -

Birch peeled mismatch

Read more -

Birch peeled bookmatch

Read more -

Birch sliced slipmatch

Read more -

Beech Mismatch

Read more -

Beech Slipmatch

Read more -

White Ash mismatch

Read more -

Brown Ash mismatch

Read more -

Brown Ash bookmatch

Read more -

Oak smoked brown

Read more -

Oak smoked black

Read more -

Oak smoked figured

Read more -

Spruce

Read more -

Pine

Read more -

Oak qtr

Read more -

Oak pippy

Read more -

Oak knotty

Read more -

Oak cr

Read more -

Maple

Read more -

Elm

Read more -

Brown Ash

Read more -

Birch sliced

Read more -

Birch burl

Read more -

Birch apple

Read more -

Beech

Read more -

Beech brown heart

Read more -

Ash white qtr

Read more -

Ash white cr

Read more -

Ash Olive

Read more -

Am White Oak

Read more -

Am Walnut

Read more -

Am Red Oak

Read more -

Am Cherry

Read more -

Alder

Read more -

Birch peeled

Read more -

Bookmatch

Read more -

Slipmatch

Read more -

Reverse bookmatch

Read more

-

BS Office3

Read more -

BS Office2

Read more -

BS Office1

Read more -

Ping Pong racket

Read more -

Baskets

Read more -

Tallink

Read more -

architectural photography

Read more -

Grand_Prize-1

Read more -

Grand_Prize-3

Read more -

Grand_Prize-4

Read more -

Grand_Prize-5

Read more -

HM-Cabinetry-Knoebel

Read more -

HM-Furniture-Grove

Read more -

HM-Furniture-Harper

Read more -

HM-Furniture-Kelly

Read more -

HM-Furniture-Valdez

Read more -

HM-Specialty_Items-Tunnicliffe

Read more -

HM-Store_Fixtures-Bernhard

Read more -

HM-Student_Design-Loew

Read more -

Specialty Items-1

Read more -

Store Fixtures-1

Read more -

Student Design-1

Read more -

Arch Woodworking 1

Read more